Celtec Expanded PVC Signboard®

Acrylite AR sheet is a continuously manufactured acrylic sheet with an abrasion resistant coating on one or two sides. This coating significantly increases the abrasion resistance and chemical resistance of the sheet while maintaining the outstanding properties associated with Acrylite FF acrylic sheet. Acrylite AR sheet combines abrasion resistance and chemical resistance with the excellent optical quality and ease of fabrication inherent to Acrylite FF sheet. Acrylite AR sheet resists marring and scratching which can be caused by frequent cleaning and/or constant public contact. Most spray painted graffiti can also be removed without damage to the sheet. The protection afforded by Acrylite AR sheet results in a harder surface thereby significantly extending the service life of the product. Care should be taken to avoid chemical contact on uncoated areas of the sheet.

Abrasion Resistance

In assessing abrasion resistance, a distinction can be made between frictional abrasion and impact abrasion. These two types of abrasion are evaluated by different test methods, Taber Abrasion and Falling Sand. An effective way to quantify the performance of an abrasion resistant coating is to report the percent change in haze after testing. Acrylite AR sheet significantly reduces the effects of both frictional abrasion and impact abrasion.

Weathering

Acrylite AR sheet withstands the adverse effects of outdoor weathering. The abrasion resistant properties are maintained during prolonged periods of outdoor use. Accelerated weathering studies indicate that there is no significant loss in light transmittance or any appreciable increase in yellowing, as measured by the yellowness index after an accelerated weathering period of three years.

Characteristics

Acrylite AR abrasion resistant sheet is a lightweight, rigid and weather-resistant thermoplastic. Acrylite AR sheets are dimensionally stable and resistant to breakage. The ease of fabrication allows the product to be used in a wide variety of applications, including the following:

- Displays

- Signs

- Menu Boards

- Transportation Glazing

- Architectural Glazing

- Museum Display Cases

- Picture Frames

- Sports Facilities

Glazing

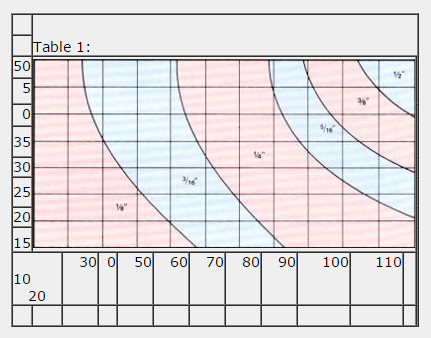

Acrylite AR sheets are recommended for use in flat, vertical, architectural glazing. Certain considerations must be taken into account before cutting sheets for installation. Acrylite AR sheets will expand and contract with a change in temperature. A 8″ panel will expand or contract approximately 0.002″ for each degree change in temperature. Calculations should be made at the installation temperature for proper sizing. In a vertical application, there will be no foreshortening due to cold flow. Slight bowing can occur under certain temperature and humidity conditions in the direction of the higher temperature or humidity. This condition is reversible. The panel will revert back to its original flatness when the temperature or humidity is equalized on both sides of the panel. Maximum wind load and window size must be considered in selecting glazing panel thickness. Table 1 gives recommended panel thicknesses for different size openings. The thickness in the graph applies to rectangular windows with widths less than 3/ of their lengths. For larger widths, use the next larger thickness. For long, narrow windows, whose length exceeds four times their width, use the next smaller thickness.

Panels ‘ x ‘ or larger need to be glazed using a dry gasket system. This allows the sheet to expand and contract while maintaining a weather-tight seal. Flexible sealants and tapes can be used for panels smaller than ‘ x ‘.

Fabrication

Acrylite AR sheets should not be fastened with bolts or screws. Localized point stresses in excess of 1 ,500 psi may cause cracking of the sheet.

Machining

Acrylite AR sheets can be sawed, routed, drilled and machined using the same techniques as Acrylite sheet products. For details on tooling and proper procedures for Acrylite AR sheet, refer to the Acrylite sheet data. When performing machining operations, keep masking applied and the work area free of chips to help prevent gouging of the sheet surface.

Panels ‘ x ‘ or larger need to be glazed using a dry gasket system. This allows the sheet to expand and contract while maintaining a weather-tight seal. Flexible sealants and tapes can be used for panels smaller than ‘ x ‘.

Acrylite AR sheets should not be fastened with bolts or screws. Localized point stresses in excess of 1 ,500 psi may cause cracking of the sheet.

Machining

Acrylite AR sheets can be sawed, routed, drilled and machined using the same techniques as Acrylite sheet products. For details on tooling and proper procedures for Acrylite AR sheet, refer to the Acrylite sheet data. When performing machining operations, keep masking applied and the work area free of chips to help prevent gouging of the sheet surface.

Edge Preparation

Scraping, wet sanding and buffing are acceptable methods to prepare a finished edge. Flame polishing is not recommended. Overspray from the flame may cause the surface coating to crack or craze. This may lead to delamination of the coating and a loss of abrasion resistance.

Cementing

Acrylite AR sheets are available with either one or two sides coated for protection against abrasion. When cementing to a non-coated sheet surface, use the same solvent or polymerizing cements commonly used for Acrylite sheet products. The most critical factor is the edge of the part to be cemented. The edge must first be properly prepared with low stresses. Annealing of the part prior to cementing is recommended. Solvent cementing to a hard coated surface cannot be readily accomplished due to the chemical resistance of the coating. To solvent cement on or to a coated surface, the coating first must be removed by sanding or routing. When removing the coating, insure that the bonding surface is flat, clean, and free of stress. Annealing the piece will insure a stress-free surface.

Thermoforming

Line bending or thermoforming Acrylite AR sheet is not recommended. The abrasion resistant, hard coat surface does not soften when heated. The coating will separate and crack in the heated region, leaving an optically poor line-bent area. This area can lose its abrasion resistant properties. Thermoforming of larger areas, even the forming of shallow domes, will result in crazing of the coated surface. Therefore, no method of heat forming is recommended for either one or two side coated products.

Cold Forming

Bending of the coated sheets into a generous radius can be done. To calculate the minimum radius of curvature, multiply the thickness of the sheet to be used by 330 for Acrylite AR sheets. Tighter radii may result in crazing or cracking of the coating and may lead to a loss of abrasion resistant properties.

Flammability

Acrylite AR sheets are combustible thermoplastics. Precautions should be taken to protect these materials from flames and high heat sources. Good judgment should be take in the use of these versatile materials and recommend that building codes be followed carefully to assure they are used properly. Acrylite AR abrasion resistant acrylic sheet usually burns rapidly to completion if not extinguished. The products of combustion, if sufficient air is present, are carbon dioxide and water. However, in many fires, sufficient air will not be available, and toxic carbon monoxide will be formed as it will from other common combustible materials.

Code Approval

Acrylite AR sheets has met the requirements to comply to the following regulations:

- ANSI Z97.1 Safety Glazing Materials Used in Building

- ANSI Z26.1 Safety Glazing Materials for Glazing Motor Vechiles

- Uniform Building Codes ICBO, BOCA, and SBCCI

- Consumer Product Safety Commission, Architectural Glazing Material Safety Standard, (16 CFR 1) Categories I & II

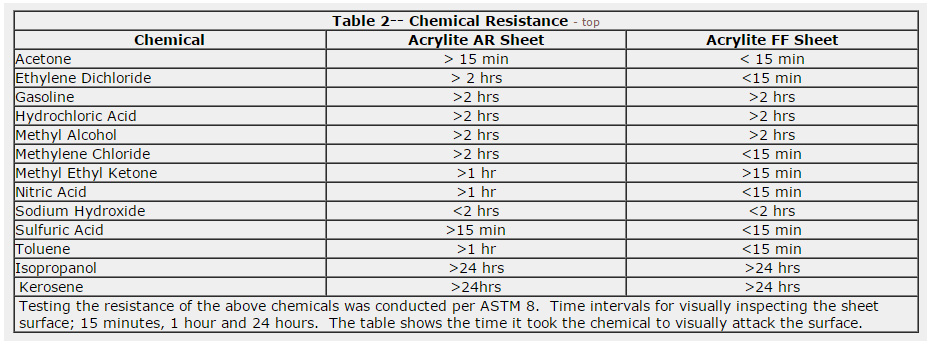

Chemical Resistance

Acrylite AR abrasion resistant sheets can withstand certain chemicals that may come in contact with the coating. Table 2 shows how the coating helps provide better protection against certain chemicals. Care should be taken to avoid contact of certain chemicals to the unprotected edges or surface of the sheet. Some of the listed chemicals may cause swelling or crazing on the uncoated side of sheets.

Cleaning

To clean off the surface of Acrylite AR abrasion resistant sheets, a liquid detergent and water solution is recommended. There are commercially available cleaners that also work well without damaging the coated surface. It is not recommended to use abrasive cleaners on the sheet surface. The following brand name cleaners have been tested and found to work well on coated surfaces.

CAUTION: Some of these cleaners may attack the uncoated side of the sheet.

Fantastik household cleaner

Mr. Clean household cleaner

Formula 409 household cleaner

Top Job household cleaner

Glass Plus cleaner

Windex window cleaner

To remove paint, ink and graffiti from the coated surface, use a soft cloth soaked in either Isopropyl Alcohol or VM&P Naphtha. Then immediately wash and rinse off residue using a liquid detergent and warm water solution. Never use mechanical methods, such as razor blades, putty knives or scrapers on the surface of the sheets. This may lead to gouging and removal of the hard coat. Once the coating has been removed, it cannot be repaired.

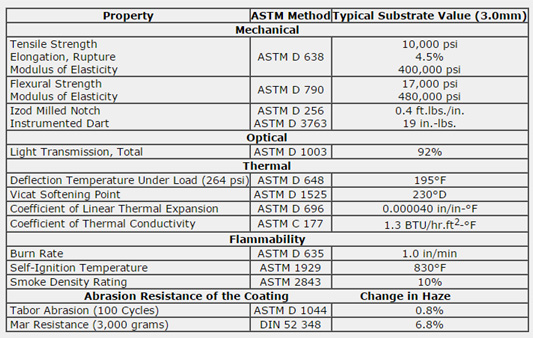

Physical Properties

Full-service plastics fabricator and supplier of plastic materials

Norva Plastics has been a full-service plastics fabricator and supplier of plastic materials. With over half a century in the business, we can tackle just about any job with confidence that comes from experience. From a tough prototype to long-run production, whatever your requirement, contact the experienced plastics fabricators first at Norva Plastics.

Norva Plastics provides many services relating to plastics and similar materials. We have 3 high precision CNC machines in house to handle high production jobs or for quick prototype jobs. We also do custom fabrication and also offer vacuum forming services. So contact us now! We look forward to serving you.