PVC Type 1®

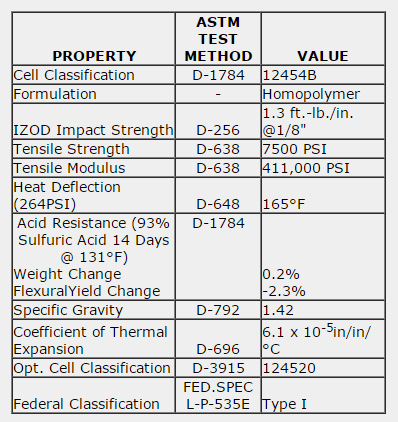

Vintec I® is a normal impact, corrosion-resistant material offering an excellent chemical resistance. (Type I Grade 1 Dark Gray PVC conforms to ASTM D1784, Class 12454-8.) Vintec I® is highly recommended for applications where the concentration of acids or alkalies are high, normal working temperatures are relatively low (140° F or below) and final installation area is not subject to excessive physical abuse.

Product Applications

Vintec I® corrosion resistant thermoplastics are engineered materials formulated to combine corrosion resistance, impact resistance, lightness, ease of fabrication and forming. Vintec I® reduces replacement costs by providing long life in harsh corrosive atmospheres.

- Utilities

- Electronics

- Chemical

- Textile

- Steel Pickling

- Pharmaceutical

- Food Processing

- Water Treatment

- Tanning

- Dyeing & Bleaching

- Fertilizer

- Waste Treatment

- Paper

- Plating

- Petroleum

- Marine

- Anodizing

- Transportation

- Acid Fume Hood and Ducts

- Acid Tank Linings

- Acid Etching Machines

- Machined Parts & Gears

- Burial Vaults

- Ceiling Materials

- Containers

- Duct & Duct Fittings

- Air Circulators

- Flues & Vents

- Industrial Surfaces

- Lab Equipment Supplies

- Machine Guards

- Noise Control Devices

- Nursery Equipment

- Pressure Switches

- Seating

- Shelving

- Storage Tanks

- Tote Boxes, Pans, & Trays

- Lightweight

- Formable

- Excellent Electrical Properties

- Impact Resistant

- Cementable

- Good Abrasion

- Resistance

- MachinableWaterproof Covers

- Acid TanksFume Scrubbers

- Machined Flanges & Valves

- BoothsBus Equipment (Interior)

- Closures

- Corrosion Control Equipment

- Dust Collection Systems

- Air Purifying Equipment

- Housings

- Industrial Waste Equipment

- Machinery

- Nuclear InstrumentsPaneling For Clean Rooms

- Scientific Apparatus

- Sheet Metal Fabrication

- Spraying Equipment

- Tanks

- Vacuum Cleaning Systems

Thermoplastic preparation for assembly (welding or other fastening methods) is similar to metal fabrication procedures. Pieces are laid out, cut, machined and joined with the same tools, equipment and skills utilized in the metalworking trades.

However, there are special forming requirements for thermoplastics not encountered in metal work. Fabrication of thermoplastics includes a wide range of operations on sheet, rod, tube and special shapes to produce finished products.

Fabrication involves cutting, sawing, machining, forming, joining or fastening together for the completed object. Machining may include beveling, routing, grinding, turning, milling, drilling, tapping and threading. The degree of skill and the quality of preparatory work in layout and various machining operations on components for fit-up are very important in assuring accurate assembly and successful fabrication.

Once the different thermoplastic parts are formed into the proper shape, they may then have to be joined.

The type and method of assembly depend on the function of the finished structure. The several assembly techniques include the use of adhesive bonding, self-tapping screws, threaded insets, press fitting, cold heading, heat joined (hot-plate welding, hot-wire welding, induction heating, hot flaring, and spin welding) cementing and hot gas welding.

Each operation requires its own tools and equipment.

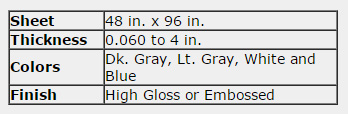

Vintec I Type 1 Grad I Rigid PVC Sheet

Full-service plastics fabricator and supplier of plastic materials

Norva Plastics has been a full-service plastics fabricator and supplier of plastic materials. With over half a century in the business, we can tackle just about any job with confidence that comes from experience. From a tough prototype to long-run production, whatever your requirement, contact the experienced plastics fabricators first at Norva Plastics.

Norva Plastics provides many services relating to plastics and similar materials. We have 3 high precision CNC machines in house to handle high production jobs or for quick prototype jobs. We also do custom fabrication and also offer vacuum forming services. So contact us now! We look forward to serving you.